EcoCool Temperature & Humidity Control Unit: ACC125

We’re excited to announce the launch of the ACC125 EcoCool – a powerful, compact upgrade for corrosion test chambers that’s easy to sell and in demand worldwide.

Benefits of the ACC125 EcoCool:

✅ Compact Design: Save valuable lab space

✅ No Refrigerant Gases: No F-Gas compliance, no certified gas engineers needed

✅ Hassle-Free Installation: No special tools or third-party contractors

✅ F-GAS Regulatory Simplicity: Ideal for EU shipping and installation

✅ Superior Control: Enhanced precision control and user interface

✅ Cost-Efficient: A fraction of the price of traditional F-Gas or CO₂ systems

✅ Test Standard Compliant: Meets IEC 60068-2-52, ISO 16701, GMW14872, VW PV1210, FORD CETP00.00-L-467, MIL 810H, and more

How It Works

The ACC125 EcoCool draws air from the chamber, chills and dehumidifies it, then returns it via insulated inlet piping. This process reduces minimum achievable temperature and humidity levels, ideal for corrosion testing and other demanding applications.

Installation Note

The unit releases heat into the surrounding room. For optimal results, the ambient temperature should be 18–23°C with a maximum relative humidity of 85%.

View the full technical datasheet here:

http://www.ascott-analytical.com/wp-content/uploads/2025/08/ACC125_EcoCool_Leaflet_A4_Print8.25_V4.pdf

Seamlessly Connected: Update Delivers New Synchronization Features

The DAS1800 is an all-in-one data acquisition system providing a comprehensive set of features to streamline the process of capturing, visualizing, and analyzing data. The latest update extends the device's scalability with new time synchronization and data sharing features.

New Hardware:

- IRIG and GPS hardware is an available factory option to assist in synchronizing multiple devices

New Software Features:

|

Visit Product Page View Datasheet

Introducing RPS8100-Meteo Barometric Pressure Sensor

Introducing Druck’s new sensor that supports the automated weather station market, and is deployed in weather stations globally!

The RPS8100-Meteo is based on Druck’s proven TERPS technology – a unique resonating silicon technology with inherent precision and stability. The TERPS technology has many qualities which surpass the technologies referenced for use as electric barometers in the WMO guide.

The RPS8100-Meteo combines a compact size and specification that is focused on delivering performance and reliability when integrated into automated weather stations.

Download the RPS8100-Meteo datasheet

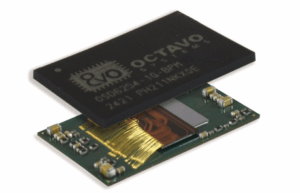

Introducing the OSD62x-PM - Our Smallest, Most Integrated SiP Yet

We’re excited to announce the official launch of the OSD62x-PM, our smallest System-in-Package to date, designed for engineers who want more performance in less space, less time, and with less risk.

Built on the TI AM62x processor family, the OSD62x-PM integrates:

- Up to 4x Arm Cortex-A53 cores + a Cortex-M4F for real-time control

- Up to 2 GB DDR4 memory

- Required passives

- All in a tiny 9 × 14 mm BGA

This single-package solution is 70% smaller than chip-down designs, cuts PCB complexity, and lets you skip DDR tuning headaches so you can focus on innovation.

Quick to Prototype

The OSD62-PM-BRK Evaluation Board is ready to ship—open hardware, with full schematics, BOM, layout files, and support for Yocto, TI SDK, and Linux BSPs.

Where It Fits Best

While general-purpose enough for any Embedded Linux project, it’s especially well-suited for:

- Dual-screen human-machine interfaces

- Edge AI and machine vision systems

- Building automation and industrial controllers

- Space-limited robotics and IoT gateways

Why It’s a Game-Changer

- Faster time-to-market: Go from concept to prototype in weeks, not months

- Smaller footprint: Free up board space for your real features

- Industrial-grade durability: −40 °C to +85 °C operating range

- Rich I/O: Dual display support, TSN Ethernet, USB, CAN-FD, and more